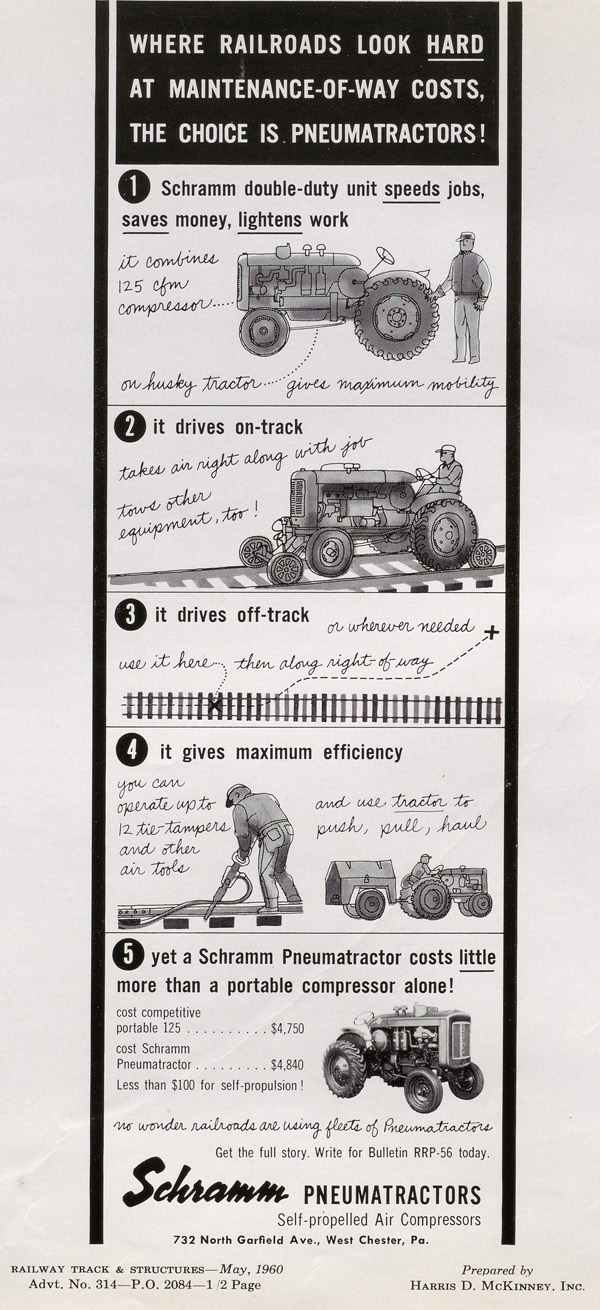

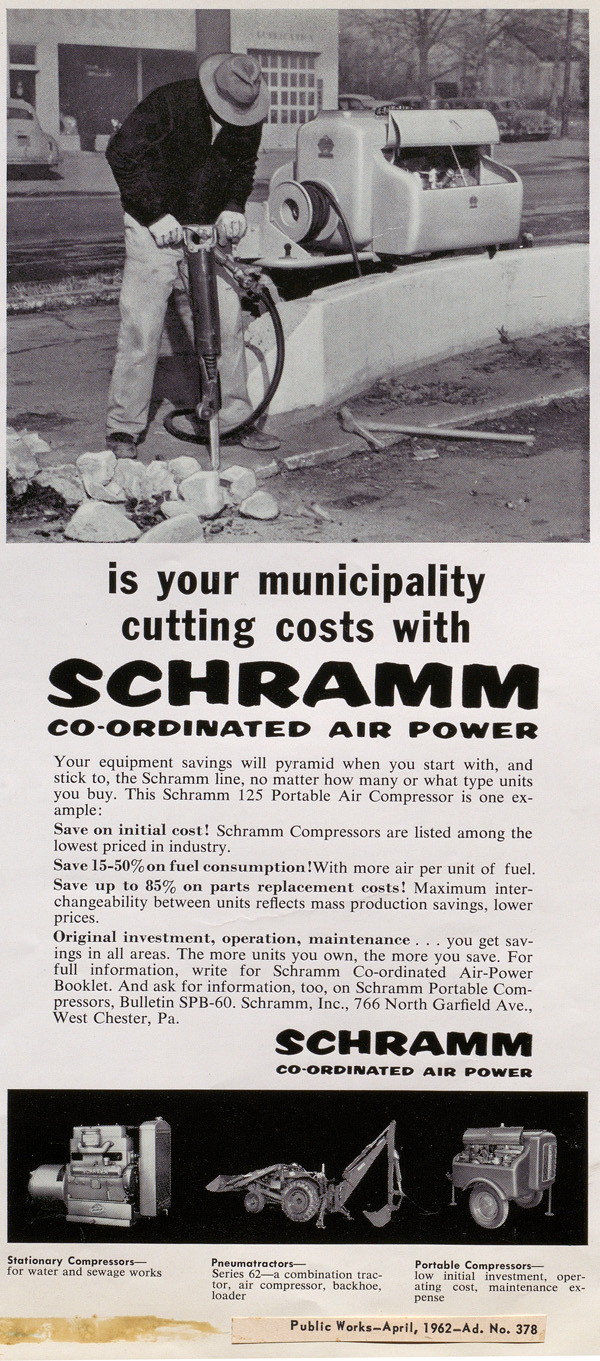

In the 1960s, Schramm emerged as a leader in the rotary drilling industry. The increased air pressure generated by the Schramm-designed and -built reciprocating air compressors on rigs increased the speed of drilling and surpassed other products on the market

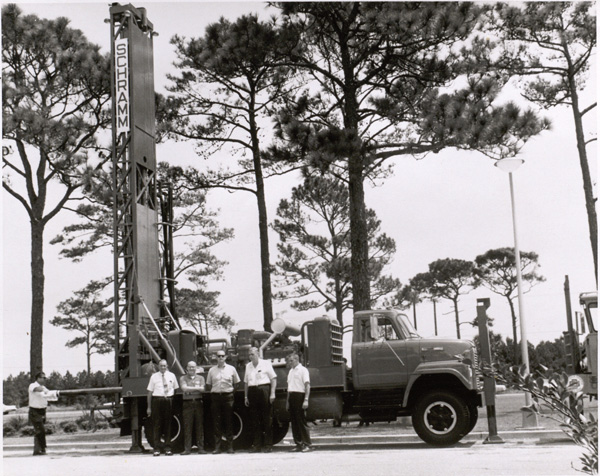

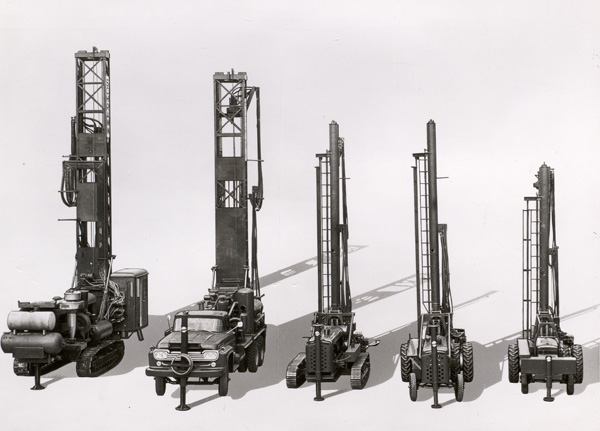

Photograph: The Schramm 'family' of Rotadrills, c.1960. See below for more photos.

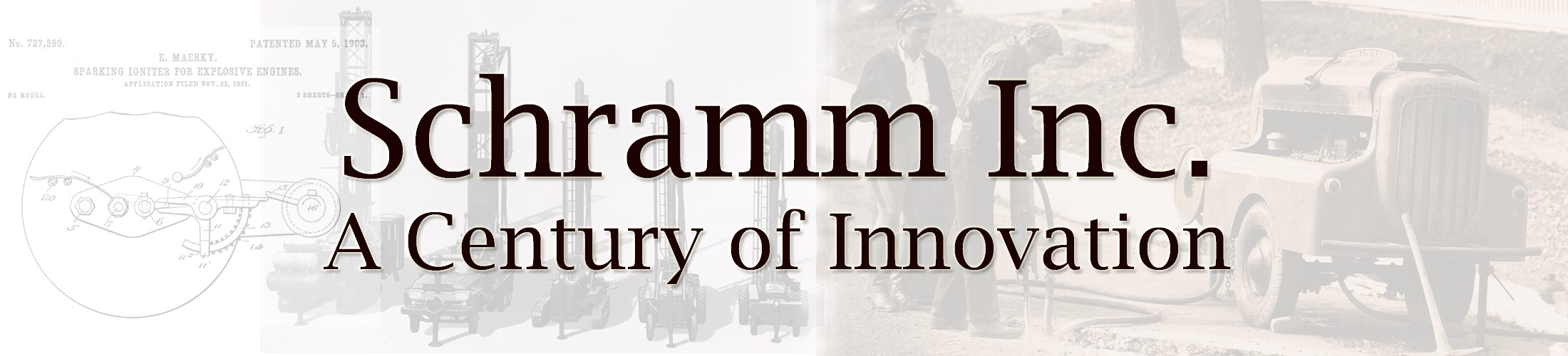

Rotadrill products, launched in 1955 with rigs on Pneumatractors for drilling holes to load explosives in quarries, evolved into truck-mounted rigs for drilling water wells. The company’s flagship product during this period was the T64HB drill rig, introduced in 1960. It proved to be a boon for water well contractors accustomed to the slow pace of conventional rigs. With the T64HB, contractors could complete one or two wells a day, drastically improving their productivity.

In the early 1960s, Schramm equipped rigs sold in Australia to mineral exploration contractors with “dual-wall” Reverse Circulation, “RC” drill pipe. This pipe-within-a-pipe system conveys compressed air through the circular space between the outside of the inner tube and the inside of the outer tube. Rock cuttings were then brought to the surface through the inside of the inner tube.

Collaborating with pneumatic tool engineer Ross Bassinger, the founder of the Bassinger Tool Company and a pioneer in the drilling industry, Schramm helped develop higher pressure DTH (“Down The Hole”) percussion drilling tools, where a hammer cracked rock prior to drilling making it more efficient. DTH tools on the market operated at lower air pressures. Bassinger’s designs operated at higher pressures, drilling faster and better holes. After the Bassinger’s designs were purchased by Mission Manufacturing, Schramm and Mission worked together to provide technical support and service to drillers throughout the world.

The company’s commitment to its employees was the focus of a 1965 Business Week article highlighting Schramm for its benefit initiatives and family-style company culture. The emphasis on employees was a hallmark of Schramm's operations throughout the decade, as evidenced by initiatives like paid holidays (1966), long-term disability insurance (1967), profit sharing, and various other benefits that solidified its reputation as a company that valued its workforce. In 1966, Schramm gave all employees a pay raise and reduced the work week from 45 to 40 hours.

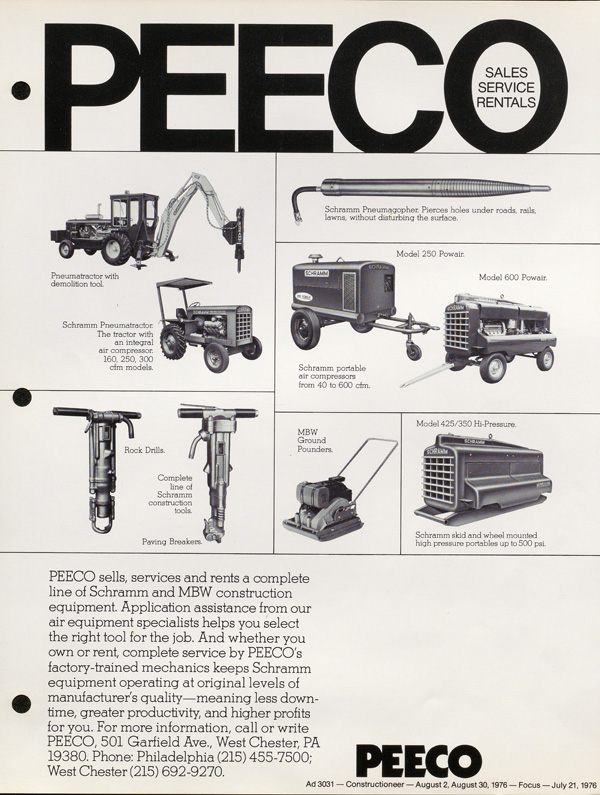

From the beginning of its air compressor business, the company sold Schramm-branded pneumatic construction tools such as paving breakers, tampers, and clay spades along with air compressors. In 1967 it moved into pneumatic tool manufacturing with the introduction of the Pneumagopher, a pneumatic underground piercing tool that tunneled under dirt or paved surfaces for the installation of pipes and wires. Manufactured at the West Chester plant, this patented tool significantly advanced the field of wire and pipe installation. Many utility companies adopted the Pneumagopher due to the advantages it brought in speed and efficiency.

In 1966, the company announced its best financial year since World War II. By the late 1960s, Schramm had become one of the leading manufacturers of rotary drill rigs in the U.S. and around the world, with products distributed worldwide.

The 1970s marked a period of rapid expansion for Schramm. The company completed several major projects, including a 40,500-square-foot metals fabrication shop in 1973 and a 13,000-square-foot machine shop in 1975. These developments showcased Schramm’s increasing capacity and its commitment to maintaining cutting-edge operations.

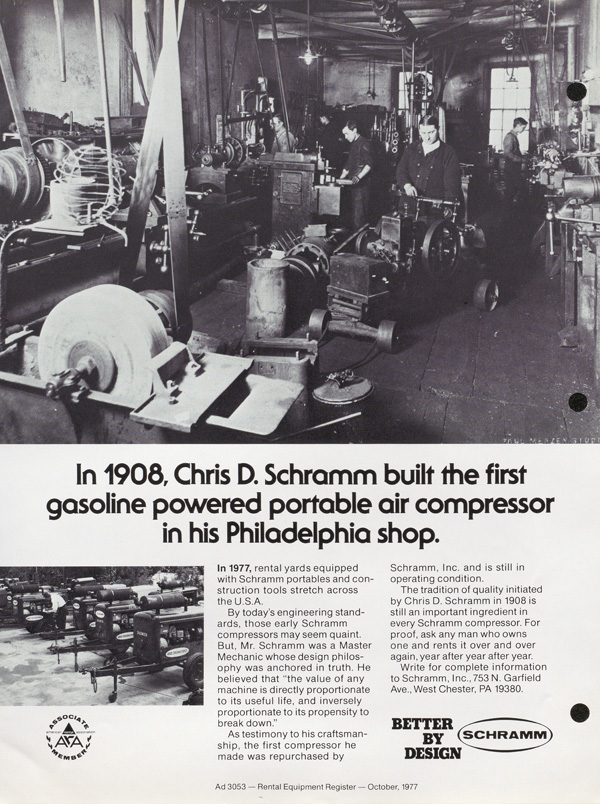

From 1972 to 1974, Schramm reported the largest sales volume in its history, with the majority of sales coming from Rotadrills. The company reported a decreasing market for air compressors. A 1979 regulation imposed by the Environmental Protection Agency affecting air compressors would further hinder the market and reinforced Schramm’s decision to shift its focus to drilling technology.

In 1975, Schramm announced agreements with Compair (England) and Atlas Copco (Sweden), two of the world’s largest manufacturers of mining equipment, to design and manufacture rotary drilling rigs branded under their respective company names.

In 1976, the company received the prestigious President’s "E" Award for its exporting accomplishments, recognizing Schramm’s prowess in international trade. Additionally, the company was honored with the International Trade Conference Award from the Pennsylvania Department of Commerce, cementing its reputation as a leader not only in drilling technology but also in global commerce.

Schramm modernized its office space and paired it with a computer-based manufacturing system to track designs, inventory, work orders, and related activities in building products. The adoption of CNC (Computer Numeric Control) machines further modernized Schramm's manufacturing operation. The transition to computer-based systems started in 1976 and reached completion in 1978.

At the end of the decade, Schramm had successfully navigated decades of growth, positioning itself as a dominant player in the global drilling market. Its focus on innovation and employee welfare helped the company maintain a leadership position throughout the 1960s and 1970s, setting the stage for continued success into the 1980s and beyond.

Jump to: 1900-1920 | 1920-1940 | 1940-1960 | 1980-2000 | 21st Century

PHOTOGRAPHS : 1960 to 1980