By the mid-1980s, Schramm had fully transitioned away from air portable compressors and construction tools, embracing its new identity as a dedicated drill rig manufacturer. It was a major shift but one that allowed the company to focus on what it did best—building reliable, high-performance drilling rigs.

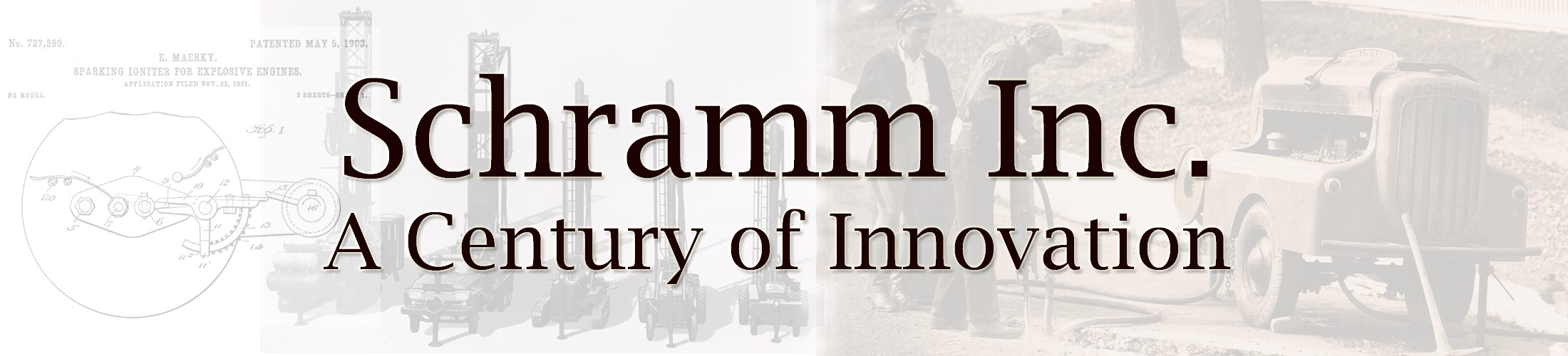

Photograph: Schramm employees outside of headquarters in West Chester, c.1995. See more photos below.

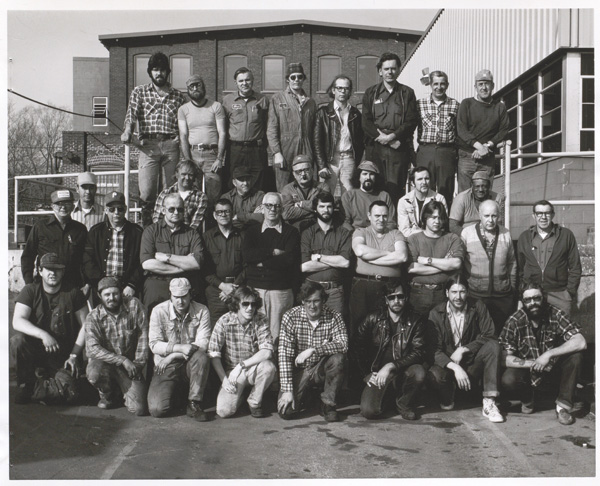

The early 1980s were a period of innovation for Schramm. The company launched the T450, T660, and T685 series, lines of small, medium, and large drilling rigs that would redefine the industry. These rigs incorporated significant technological enhancements—high pressure rotary screw air compressors replaced the outdated reciprocating air systems, drill rod and bit rotation systems were modernized, and truck-mounted rigs became increasingly advanced.

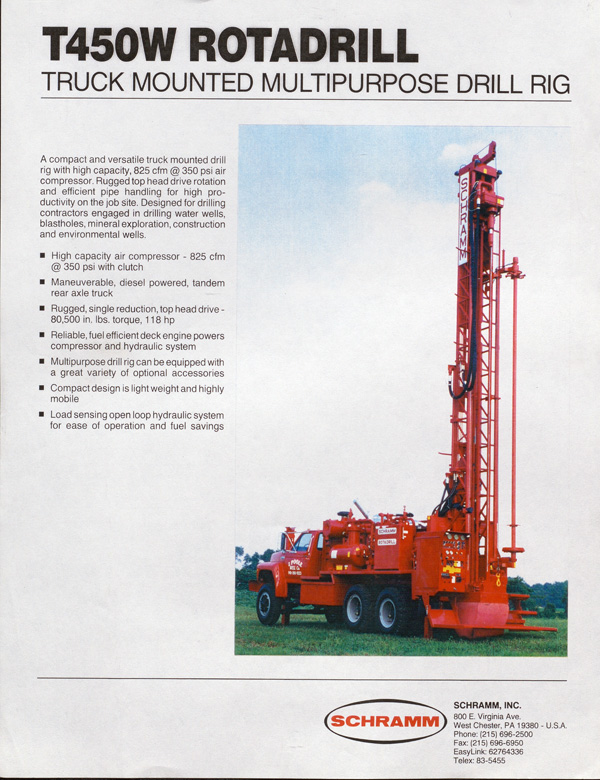

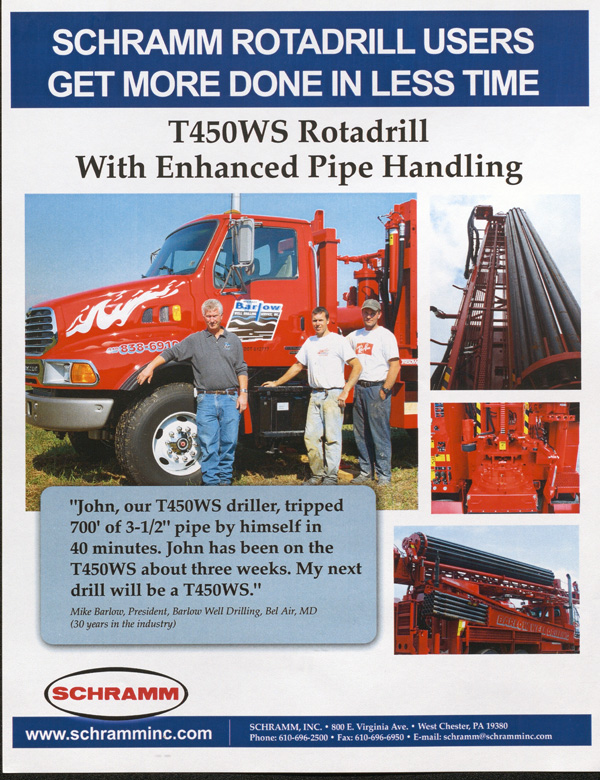

Then, in 1984, a major breakthrough occurred with the release of the T450. Lightweight, maneuverable, and cost-effective, it quickly became the gold standard for the water well industry. In fact, it became the best-selling water well rig in the U.S., solidifying Schramm’s reputation for innovation and reliability.

In 1985, Dick Schramm, who had been with the company since 1961, was appointed president. He guided the new focus on developing and marketing modern rotary drilling rigs, building on the company’s history of innovation.

During the 1980s, Schramm faced rising competition in the blasthole drilling market. Larger companies dominated the field, highlighting that Schramm’s true strength lay in water and exploration drilling. The company responded by pushing the limits of its technology, creating its largest-ever TM drilling rig. This model introduced a revolutionary "top-head" rotary drill design, where the bit was rotated from the top of the drill rod instead of using the traditional ground-level Kelly and rotary table setup. Even more impressively, it featured an automated, hands-free rod handling system—laying the groundwork for what would later become the LOADSAFE system in Schramm’s Telemast and oil and gas rigs.

By the 1990s, Schramm’s customer base had grown. Their rigs attracted customers from a variety of specialized applications, including mineral exploration, geothermal drilling, mine rescue operations, and even “grade control” drilling to help mining companies determine how to process ore. As the need for more advanced and versatile rigs grew, Schramm developed new features like sliding angle masts, which allowed drilling at 45-degree angles to better access underground strata.

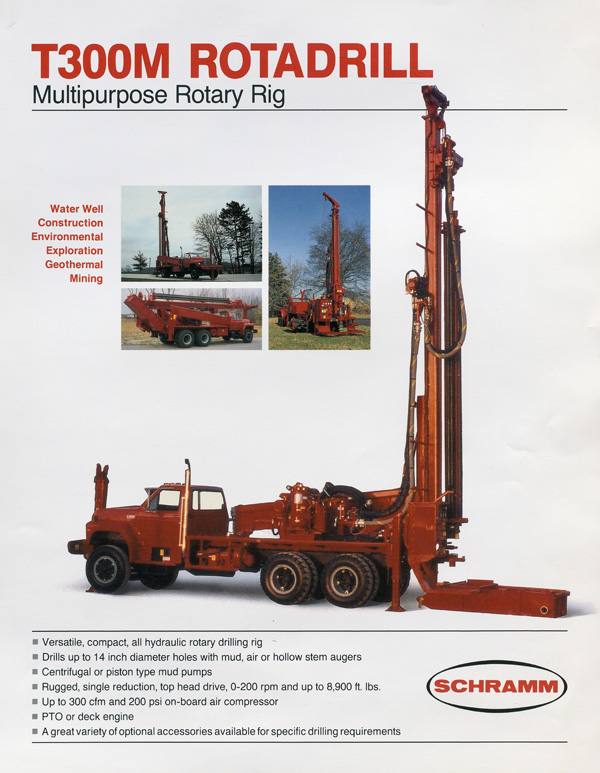

Some of the company’s most significant advancements occurred in the closing decades of the 20th century. The introduction of the T300 series in 1991 marked a major step forward for contractors working in soft, unconsolidated geological formations. Unlike Schramm’s earlier rigs which used compressed air, these rigs used mud pumps to flush cuttings from the borehole—a method known as mud drilling. Mud drilling had long been the prevalent technique in the industry, and its dominance opened up new sales opportunities.

In 1998, Schramm introduced the SCH30GC Model, a grade-control rig that combined Schramm’s tracked platforms with the sliding angle mast (SAM) technology developed for mineral exploration rigs. The result was a powerful and versatile machine that found application in the mining industry and geothermal heat pump drilling.

The decade ended on a high note. In 1999, Schramm introduced the TM200 deep exploration rig, which featured a groundbreaking innovation—the automated drill rod handling system. This technology would go on to become a crucial component of Schramm’s groundbreaking “TX” Telemast rig series, setting the stage for the company’s next era of success.

Jump to: 1900-1920 | 1920-1940 | 1940-1960 | 1960-1980 | 21st Century

PHOTOGRAPHS : 1980 to 2000